+353 42 93 73413

+353 42 93 73413 info@sft.ie

info@sft.ie Mon - Fri 09.00 - 17.00

Mon - Fri 09.00 - 17.00- View our Brochure

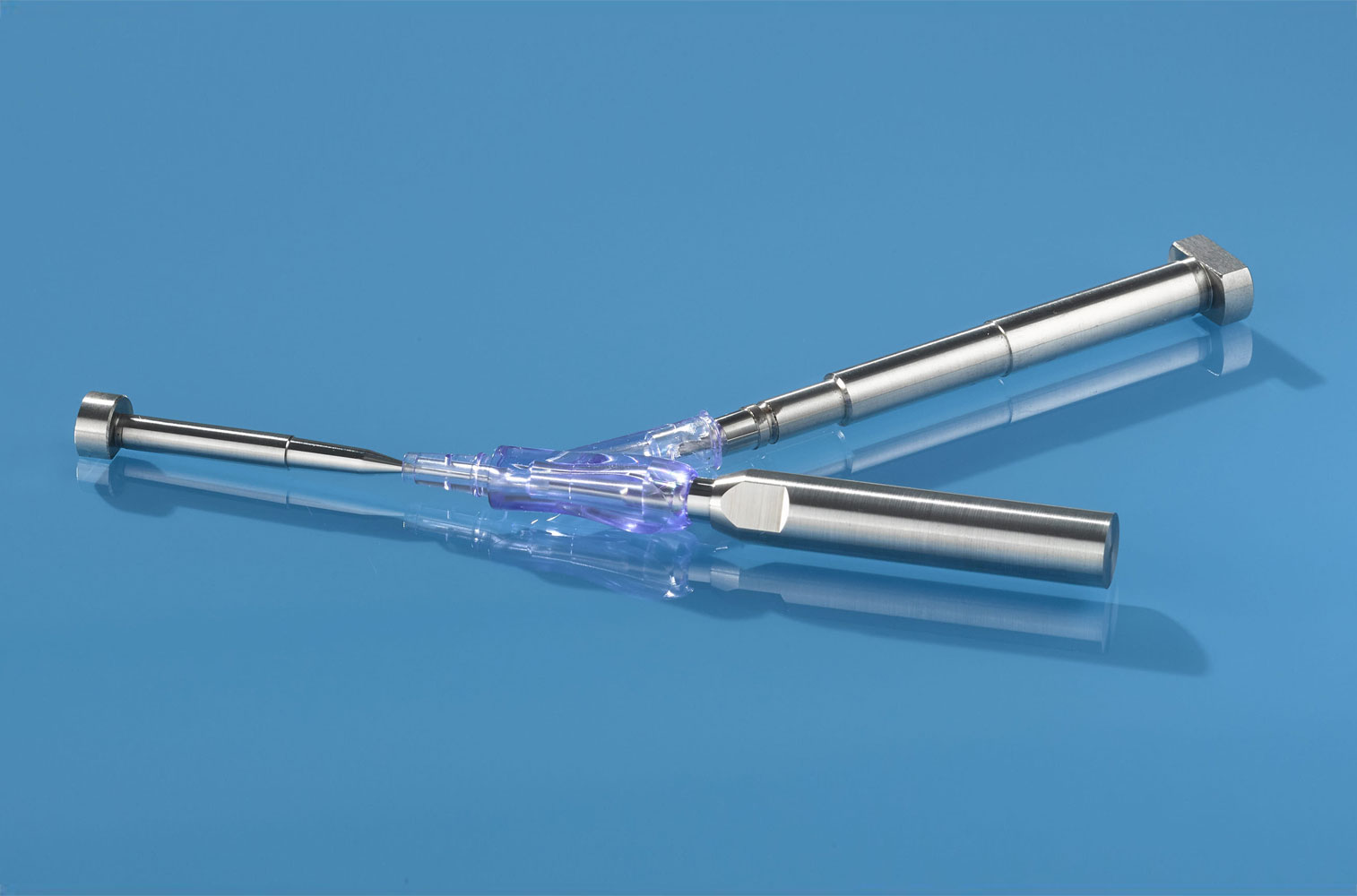

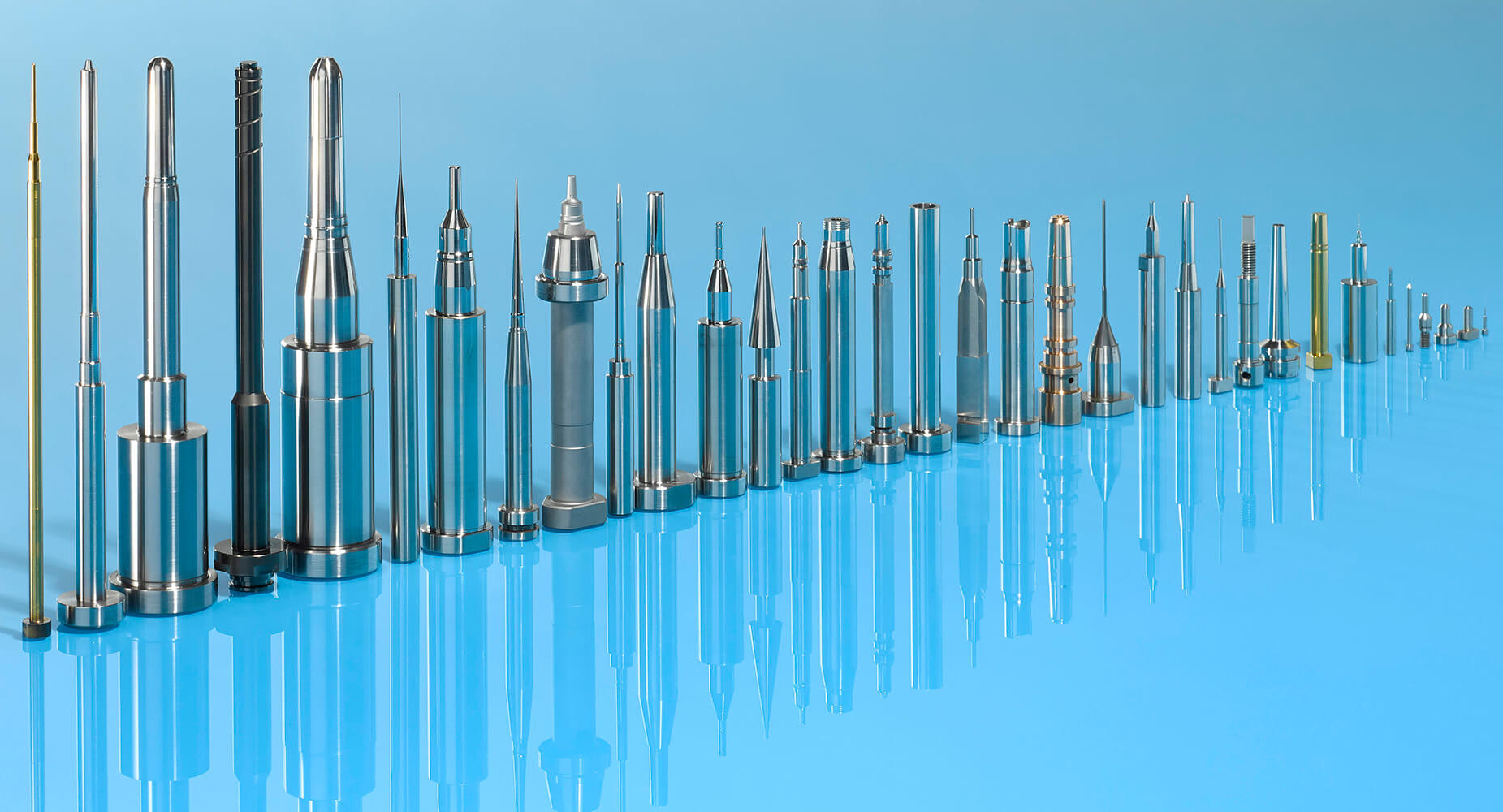

OUR PRODUCTS

-

We have a solid reputation based on trust, innovation and professionalism. We have extensive experience working with a wide variety of materials including Stainless Steel, Tool Steels, Aluminium, Brass, Copper, Moldmax and various Plastics, producing customised parts for a wide range of industrial uses. We can supply one-off prototypes through to production volumes. At SFTD we pride ourselves in offering the shortest possible turnaround times to ensure the best support and service to our customers.

QUALITY

SFTD has a long tradition of providing a high quality service to our clients by holding our components to the highest standards possible. We are an ISO 9001:2015 Quality Management Systems certified company. Quality is embedded as part of our company culture and sets us apart from competitors. On every order we guarantee delivery on time and to customers exact specifications. We incorporate quality control and documentation throughout our production process, from raw material certification and traceability through to final inspection and dimensional reports. All of these procedures and checks ensure we produce only the highest quality parts every time.

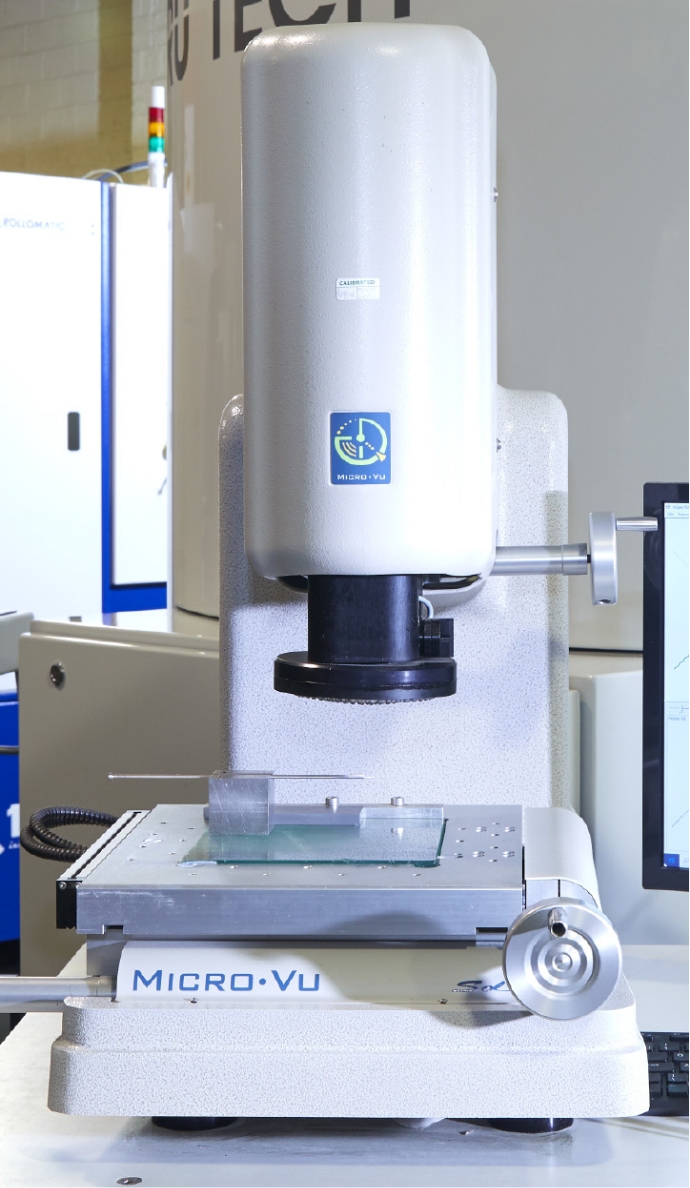

To ensure the production of components are both precise and accurate, we have a custom temperature controlled metrology department. All final inspections are carried out under repeatable conditions using the latest measuring machines and technology available, ensuring quality products Care repeated time and again.

Amongst our various micrometers, heights gauges, bore gauges, calipers, slip gauges and other inspection equipment, our metrology department also has :

- CNC CMM Keyence 2100 machine

- 2 VMM automated Micro Vu Sol measuring machines.

- 2 microscope shadow graphs

- Surface Finish Testing machine

Click here to make an enquiry

Click here to make an enquiry