+353 42 93 73413

+353 42 93 73413 info@sft.ie

info@sft.ie Mon - Fri 09.00 - 17.00

Mon - Fri 09.00 - 17.00- View our Brochure

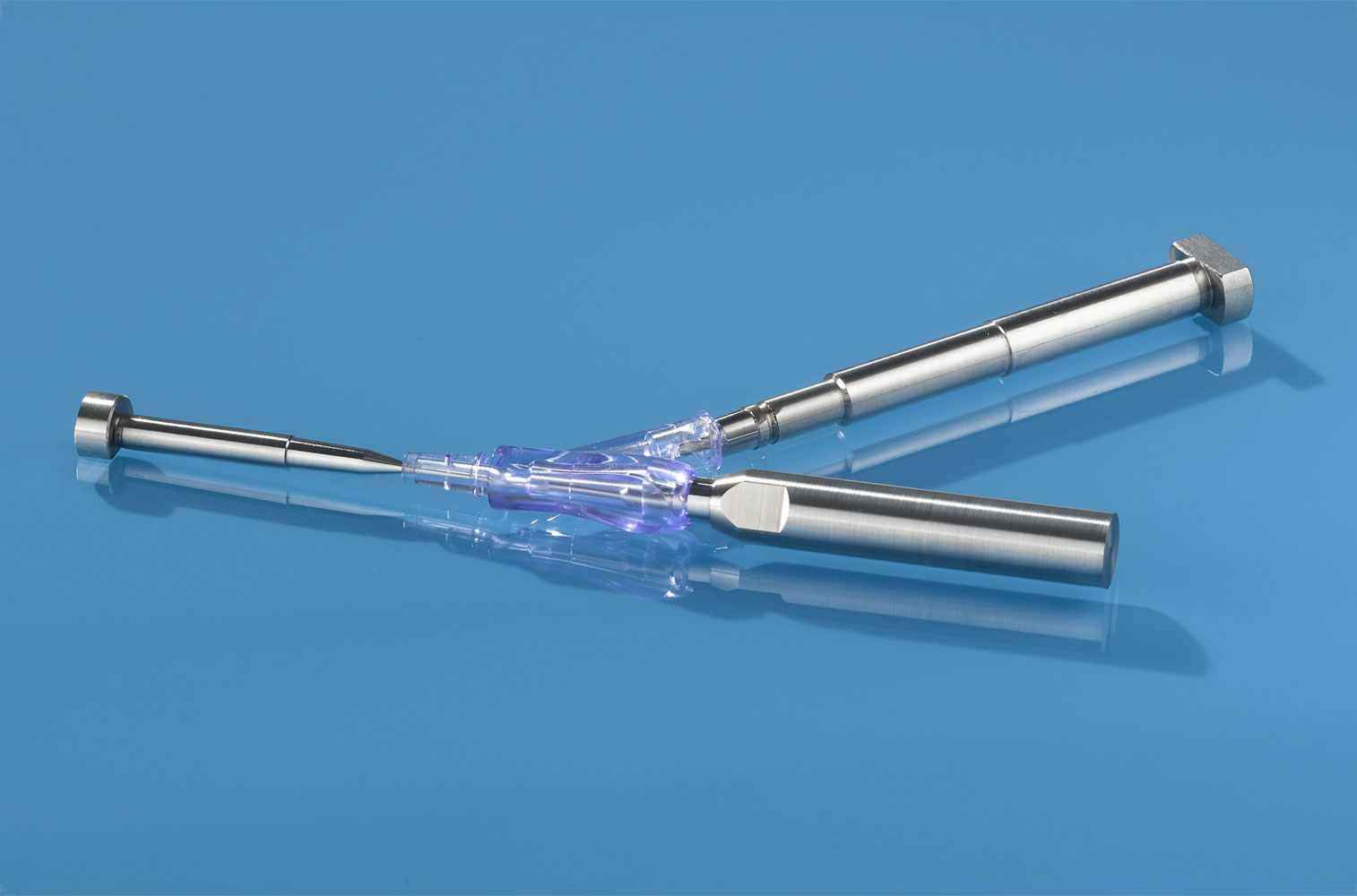

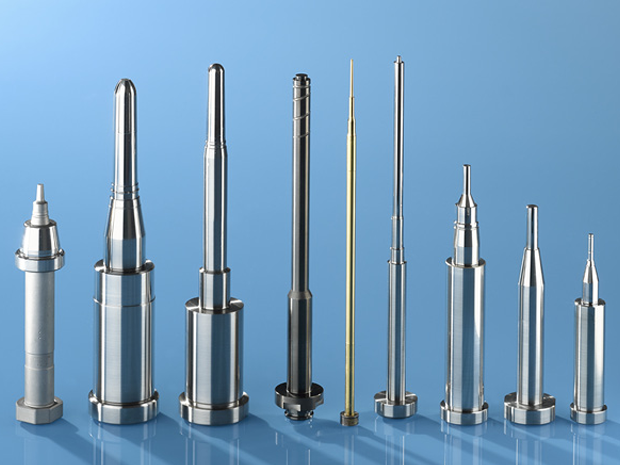

SFTD recently invested in a 5 axis precision cylindrical grinding machine with integrated 3 axis robot loader, this machine is ideal for grinding core pins allowing for a diameter range of 0.025 – 25mm.

The Rollomatic NP50’s unique grinding system means it is possible for us to achieve a run out of 0.001mm on our products. Multiple functions can be carried out in one chucking set-up, we also have the ability to grind both threads and flats.

Precision and repeatability are monitored throughout production with a built in automated measuring system. The machine allows for automation of production, which drives efficiencies, delivering quicker turn around times for clients. The Rollomatic NP50 machine uses CBN grinding wheels which we dress on site with our Farman FC250 wheel dressing machine.

OTHER SERVICES, EQUIPMENT & CAPABILITIES

With recent investment we have upgraded our workshop to include some of the best machining centres available, this puts us in an industry leading position to meet customer requirements now and into the future. To keep up with the evolving needs of our customers and the industry we will continue to invest in the latest machines and technology to maintain our position as leader in the precision engineering sector.

Our Equipment also includes:

- HURCO CNC Milling machines

- MAZAK Turning Centres

- ROBBI CNC Cylindrical Grinding Machine

- ROLLOMATIC NP50 Grinding Machine with Robotic Loader

- JONES and SHIPMAN CNC and manual Surface Grinders

- DEDTRU Centreless Grinding machines

- SODICK EDM Erosion machines

- SODICK EDM Wire Erosion Machine

- SODICK fast hole drilling EDM Machine

- CNC Profile grinding machine

- Plunge Grinding machine

- LASER precision welder

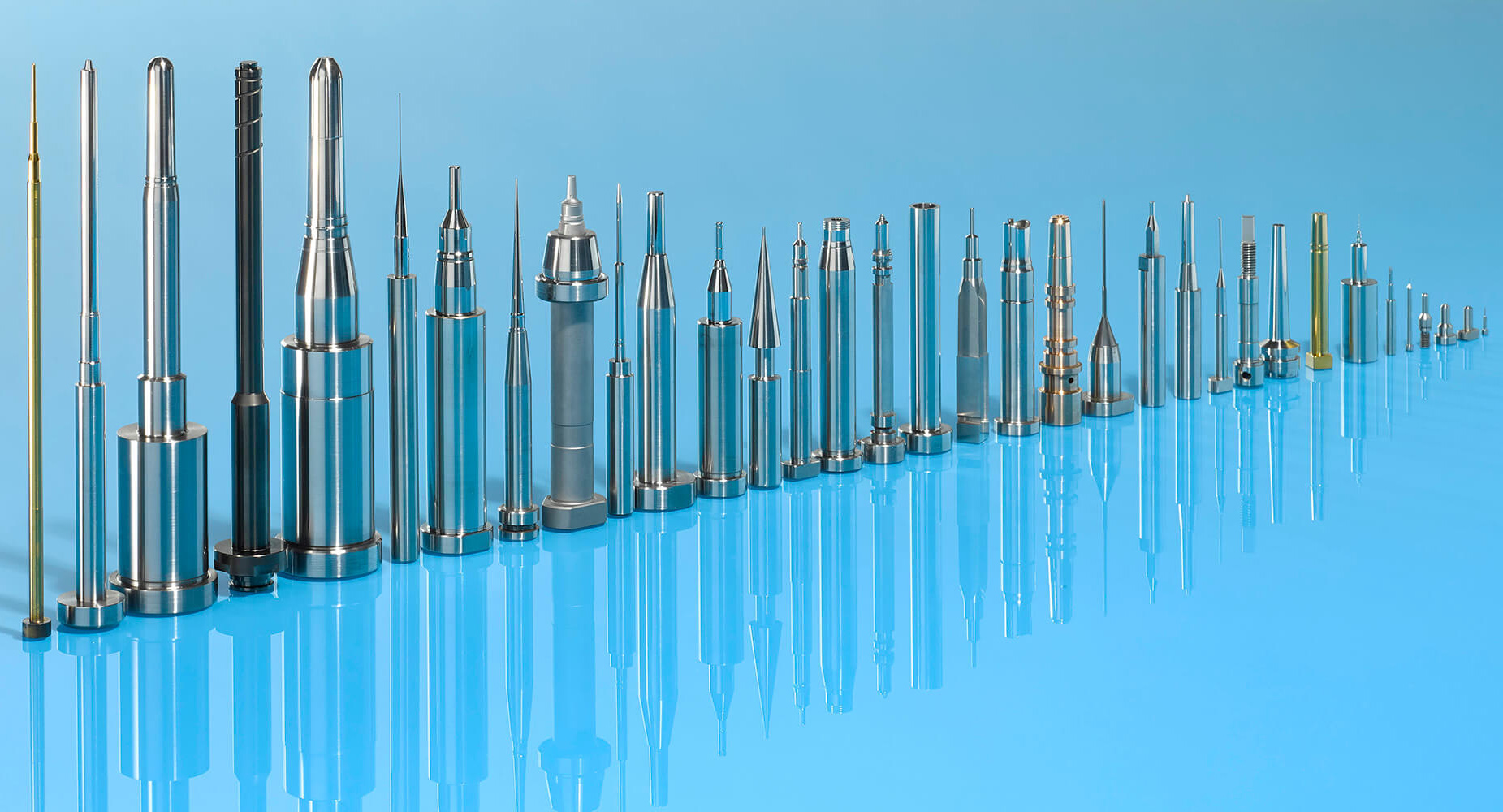

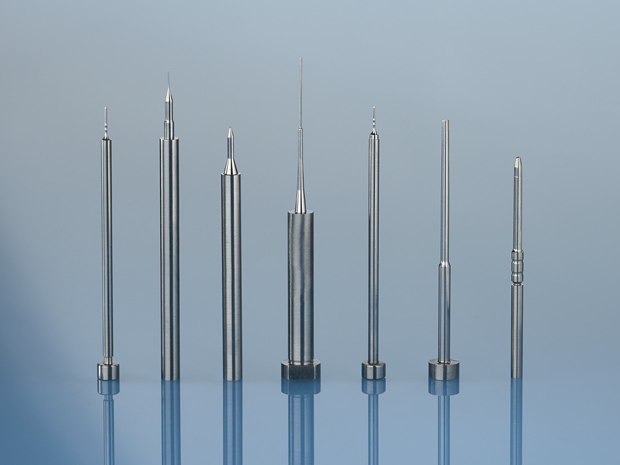

OUR PRODUCTS

At SFTD we are committed to not only meeting the needs of our clients in terms of quality, delivery times and cost.

View our Products

View our Products